the environmental impact of ev manufacturing: beyond zero emissions

the environmental impact of ev manufacturing: beyond zero emissions

Electric vehicles (EVs) have taken center stage in recent years as a key solution to reducing greenhouse gas emissions and combating climate change. While much of the focus has been on the zero-emission capabilities of EVs during their operational life, it’s essential to understand the broader environmental impact of their manufacturing processes. This article delves into the implications of EV production, examining the carbon footprint, resource extraction, and recycling challenges that come along with this promising technology.

Carbon Footprint of EV Manufacturing

One of the most significant components of electric vehicle manufacturing that affects the environment is its carbon footprint. Building an electric vehicle, especially its battery, involves processes that are energy-intensive and often rely on fossil fuels.

According to a study by the International Council on Clean Transportation (ICCT), producing the battery of an electric vehicle can generate large amounts of CO2. The production process may emit between 61 to 106 kilograms of CO2 per kilowatt-hour of battery capacity. Given that the average EV battery has a capacity of about 60 kWh, the carbon footprint can be substantial even before the vehicle hits the road.

That said, it’s important to emphasize that, over the lifespan of an EV, the total emissions are often significantly lower compared to internal combustion engine (ICE) vehicles. This is especially true if the EV is charged using renewable energy sources.

Resource Extraction and Impact

The production of EV batteries requires the extraction of several key minerals such as lithium, cobalt, and nickel. These resources are often located in regions where mining practices can be environmentally destructive and socially exploitative.

Lithium

Lithium, a crucial component for EV batteries, is predominantly extracted from salt flats in South America and mineral ores in Australia. The extraction process, particularly from salt flats, is water-intensive, which can deplete local water resources and impact local agriculture. Furthermore, the chemical runoff from lithium mining can pollute local water supplies and harm ecosystems.

Cobalt

Cobalt mining, primarily sourced from the Democratic Republic of the Congo (DRC), poses significant ethical and environmental challenges. Mining operations in the DRC have been associated with human rights abuses, including child labor and unsafe working conditions. Environmentally, cobalt mining can lead to soil contamination, air pollution, and deforestation.

Nickel

Nickel mining also has substantial environmental impacts. It involves practices that can lead to soil degradation, water pollution, and the release of sulfur dioxide, contributing to acid rain. As demand for nickel increases with EV adoption, these environmental concerns may become more pronounced.

Manufacturing Efficiency and Technological Advancements

Despite these challenges, ongoing advancements in battery technology and manufacturing processes are aiming to reduce the environmental impact of EV production.

Recycling and Reuse

Battery recycling technologies are rapidly developing to recover valuable materials and reduce the need for new mining. Companies like Redwood Materials and Li-Cycle are pioneering methods to recycle lithium-ion batteries, aiming to reclaim over 95% of the essential metals. Moreover, the concept of second-life applications is gaining traction, where used EV batteries are repurposed for renewable energy storage systems.

Improved Manufacturing Processes

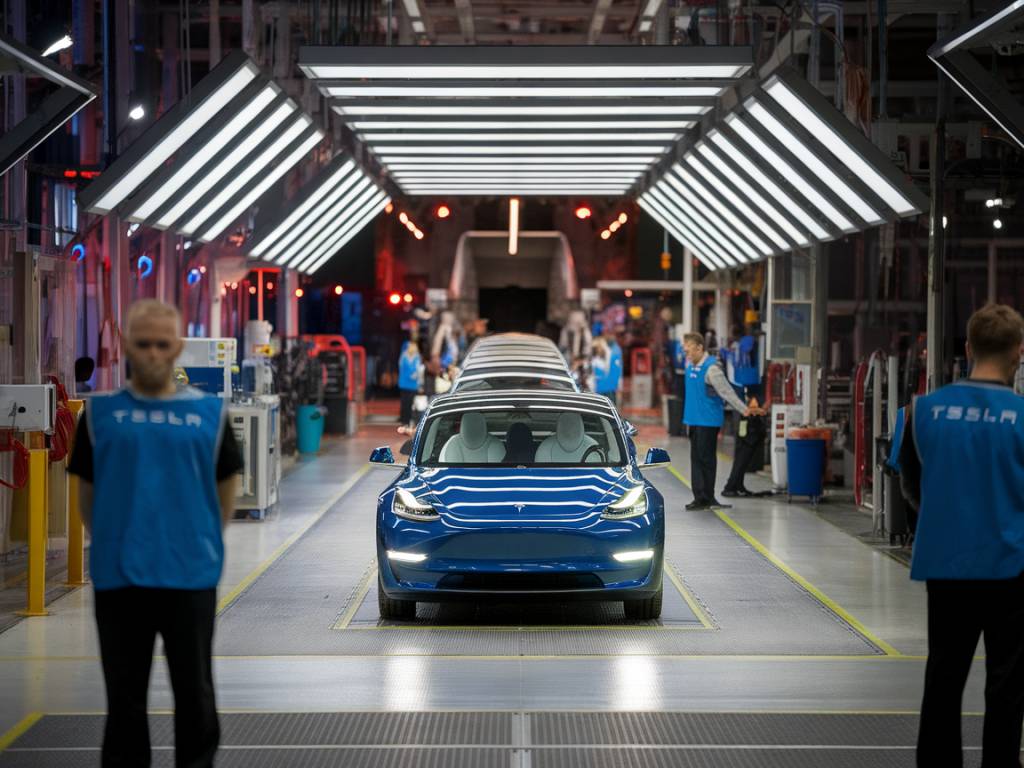

Car manufacturers are increasingly investing in renewable energy for their production facilities to lower the carbon footprint of EV manufacturing. Tesla’s Gigafactory, for example, aims to be powered entirely by renewable energy sources, significantly reducing emissions associated with battery production.

Moreover, newer battery chemistries such as solid-state batteries promise to be more energy-dense and environmentally friendly. These advancements could lead to fewer resource requirements and minimized environmental impact.

Comparing EVs to Internal Combustion Engine Vehicles

While it’s crucial to acknowledge the environmental impacts of EV manufacturing, it’s equally important to compare these impacts to those of traditional internal combustion engine (ICE) vehicles.

ICE vehicles not only produce significant emissions during their operational life but also involve energy-intensive extraction and refinement processes for fossil fuels. The cumulative impact of operational emissions, fuel production, and vehicle manufacturing makes ICE vehicles considerably more detrimental to the environment than EVs.

Government Policies and Regulations

Government initiatives and policies are increasingly focusing on sustainable manufacturing practices for EVs. Policies such as the European Union’s Battery Directive aim to ensure environmentally responsible battery production, including rules for battery recycling and the use of sustainable materials.

In the United States, the Biden administration’s Electric Vehicle Charging Action Plan and initiatives like the American Jobs Plan are putting a spotlight on green technology and sustainable manufacturing, with substantial investments in EV infrastructure and clean energy.

The Road Ahead: Challenges and Opportunities

The transition to electric vehicles offers both challenges and opportunities in terms of environmental sustainability. On one hand, the resource-intensive nature of battery production and the ethical and environmental issues in mining pose significant hurdles. On the other hand, advancements in recycling technologies, improved manufacturing processes, and supportive government policies present opportunities to mitigate these impacts.

Ultimately, the key to minimizing the environmental footprint of EV manufacturing lies in continued research and innovation. By investing in sustainable materials, enhancing recycling capabilities, and adopting renewable energy in production, the automotive industry can make strides towards truly green transportation solutions.

For consumers, understanding the broader environmental impact of EV manufacturing is essential for informed decision-making. While the journey towards sustainable transportation is complex, the benefits of reducing operational emissions and promoting green technology make electric vehicles a vital component of our efforts to combat climate change.